WHAT IS THE BEST MATERIAL FOR BULLETPROOF HELMET?-CHINABALLISTIC.COM

The best material for a bulletproof helmet depends on various factors such as the specific threats it needs to withstand, weight considerations, and cost. Some common materials used in the construction of bulletproof helmets include:

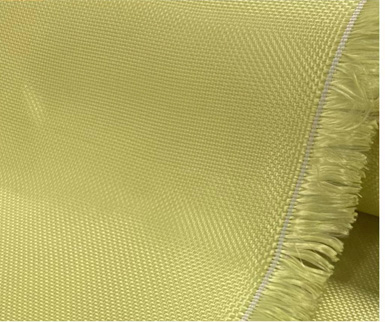

Aramid fibers (e.g., Kevlar): Aramid fibers are lightweight and have high tensile strength. They are commonly used in soft armor to protect against handgun rounds and fragmentation.

Dyneema: Dyneema is another high-performance fiber known for its strength and lightness. It is often used in combination with other materials to create lightweight and effective ballistic protection.

UHMWPE (Ultra-High Molecular Weight Polyethylene): This material offers excellent strength and impact resistance, making it suitable for bulletproof applications. It is also commonly used in body armor.

Composite materials: Some helmets may use a combination of different materials, such as aramid and UHMWPE, to optimize protection, weight, and comfort.

Ceramic plates: In some advanced military helmets, ceramic plates are used to provide additional protection against high-velocity rifle rounds. These plates are often used in conjunction with other materials to create multi-hit capable helmets.

The choice of material will depend on the intended use of the helmet. Military and law enforcement personnel may require more robust helmets capable of stopping high-velocity rifle rounds, while civilians may opt for lighter helmets that offer protection against handguns and low-velocity projectiles.

It’s essential to remember that no a helmet can provide 100% protection against all threats, and ballistic protection should be part of a comprehensive approach to personal safety and situational awareness. If you are in a profession that requires body armor or a bulletproof helmet, it’s crucial to consult with experts and follow the guidelines set forth by relevant authorities to ensure you have the appropriate protection for your needs.

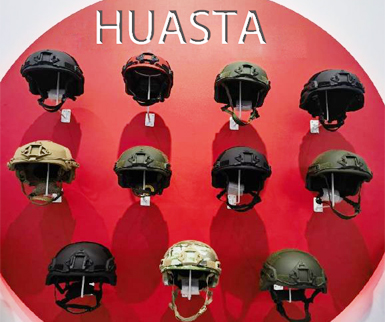

GUANGZHOU HUASTA INDUSTRIAL has been manufacturing and offering the bulletproof helmets to clients since 2001, every product pass through the SHOOTING TEST, quality is guaranteed. We can offer you the bulletproof helmet with the best material that fit you. If you have any interest, please don’t hesitate to contact us by admin@HuastaTactical.com.