UNDERSTANDING THE IMPORTANCE OF BULLETPROOF PLATE

Outline:

1. Introduction

2. What are Bulletproof Plates?

– Definition and Purpose

– Types of Bulletproof Plates

3. How Bulletproof Plates Work

– The Science Behind Protection

– Material Composition

4. Benefits and Applications

– Military and Law Enforcement Use

– Civilian Applications

5. Factors to Consider Before Purchasing

– Protection Levels

– Weight and Comfort

– Durability and Maintenance

6. Training and Proper Use

– Importance of Training

– Handling and Maintenance Tips

7. Innovations in Bulletproof Plate Technology

– Lightweight Materials

– Flexible and Multi-Threat Plates

8. Common Misconceptions

– Full Protection Guarantee

– Body Armor as Invincibility

9. The Ethical Debate

– Civilian Use and Concerns

– The Responsibility of Wearing Body Armor

10. Conclusion

Understanding the Importance of Bulletproof Plates

- Introduction

In today’s unpredictable world, personal safety and protection have become paramount for individuals from all walks of life. As the need for enhanced security increases, so does the demand for effective means of self-defense. One such solution that has gained prominence is bulletproof plates. This article aims to shed light on the significance of these plates in safeguarding lives and their growing relevance in various applications.

2. What are Bulletproof Plates?

2.1 Definition and Purpose

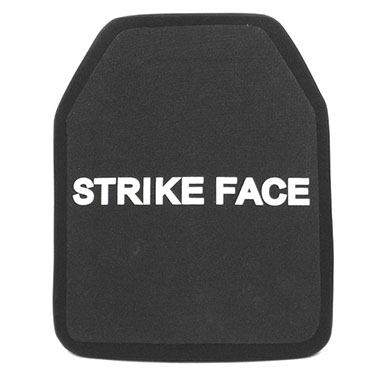

Bulletproof plates, also known as ballistic plates or body armor plates, are specialized protective equipment designed to absorb and dissipate the impact of bullets, shrapnel, or other projectiles. These plates are commonly used in conjunction with bulletproof vests or plate carriers to provide an extra layer of protection to the wearer.

2.2 Types of Bulletproof Plates

There are several types of bulletproof plates available, each offering different levels of protection and features. Some common types include:

– Ceramic Plates: These are made from hard ceramic materials and are effective at stopping high-velocity rounds.

– Steel Plates: Steel plates offer robust protection but can be heavier than other materials. What’s more, the bullet will jump result in the second harm on people around the wearer.

– Polyethylene Plates: These plates are lightweight and provide reliable protection against multiple shots.

3. How Bulletproof Plates Work

3.1 The Science Behind Protection

Bulletproof plates work on the principle of dispersing the kinetic energy of the bullet upon impact. When a bullet strikes the plate, the energy is spread across a wider area, reducing the force exerted on a specific point.

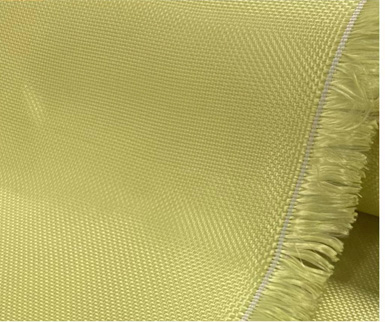

3.2 Material Composition

The choice of materials used in bulletproof plates plays a crucial role in their effectiveness. Manufacturers often use a combination of high-strength materials such as aramid fibers, ceramic composites, and ultra-high-molecular-weight polyethylene (UHMWPE) to create plates that offer the desired level of protection.

4. Benefits and Applications

4.1 Military and Law Enforcement Use

Bulletproof plates have been extensively adopted by military and law enforcement agencies worldwide. These plates provide reliable protection to personnel in high-risk situations, such as combat zones and tactical operations.

4.2 Civilian Applications

Beyond military and law enforcement use, bulletproof plates have found applications in the civilian sector. Private security personnel, journalists reporting from conflict zones, and individuals concerned about personal safety can benefit from the added protection offered by these plates.

5. Factors to Consider Before Purchasing

5.1 Protection Levels

Bulletproof plates come in various protection levels, ranging from Level IIa to Level IV, with Level IV providing the highest level of protection against armor-piercing rounds. Understanding the threat level you may face is essential in choosing the appropriate plate.

5.2 Weight and Comfort

While protection is crucial, the weight and comfort of bulletproof plates also play a significant role, especially for extended wear. Lighter materials like UHMWPE offer improved comfort without compromising on safety.

5.3 Durability and Maintenance

Investing in durable and well-maintained bulletproof plates ensures their longevity and effectiveness. Regular inspection and maintenance are vital to keep the plates in optimal condition.

6. Training and Proper Use

6.1 Importance of Training

Owning bulletproof plates alone is not sufficient; proper training in their use and maintenance is equally vital. Without adequate training, the wearer may not fully utilize the protective potential of the plates.

6.2 Handling and Maintenance Tips

Learning how to handle, store, and clean bulletproof plates correctly ensures their performance remains uncompromised over time. Manufacturers’ guidelines should be followed for maintenance.

7. Innovations in Bulletproof Plate Technology

7.1 Lightweight Materials

Advancements in material science have led to the development of ultra-lightweight bulletproof plates without compromising on protection levels. These plates are ideal for individuals seeking increased mobility.

7.2 Flexible and Multi-Threat Plates

Innovative designs now offer flexibility in bulletproof plates, making them more comfortable to wear while maintaining their ability to protect against a variety of threats.

8. Common Misconceptions

8.1 Full Protection Guarantee

While bulletproof plates provide excellent protection, it is essential to remember that no protective gear can guarantee complete invincibility. Remaining cautious and vigilant is still crucial.

8.2 Body Armor as Invincibility

It’s essential to educate users that wearing bulletproof plates doesn’t make them invulnerable. Responsible use and situational awareness are equally vital in ensuring personal safety.

9. The Ethical Debate

9.1 Civilian Use and Concerns

The use of bulletproof plates by civilians raises ethical questions about the increasing militarization of society and its potential impact on interpersonal interactions.

9.2 The Responsibility of Wearing Body Armor

Wearing body armor, including bulletproof plates, comes with a responsibility to use it legally and ethically. Understanding the laws and regulations surrounding body armor usage is crucial.

10. Conclusion

Bulletproof plates have become a vital tool in safeguarding lives, not only for military and law enforcement personnel but also for civilians seeking added protection. With advancements in technology, these plates have evolved to be more effective and comfortable. However, it is crucial to remember that no protective gear can guarantee complete invincibility. Responsible use, coupled with proper training and awareness, ensures that bulletproof plates serve their purpose effectively, contributing to personal safety and security.

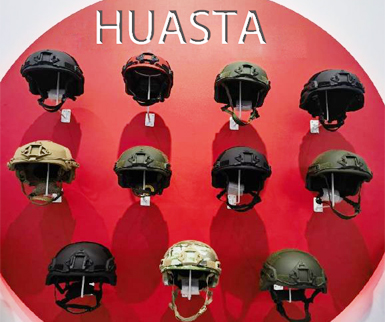

GUANGZHOU HUASTA INDUSTRIAL has been manufacturing and offering the bulletproof plates to clients since 2001, every product pass through the TEST, quality is guaranteed. We can offer you the bulletproof helmet with the best material that fit you. If you have any interest, please don’t hesitate to contact us by admin@HuastaTactical.com.

FAQs

1. Q: Can bulletproof plates stop all types of bullets?

A: No, bulletproof plates have different protection levels, and their ability to stop bullets varies depending on the plate’s material and protection rating.

2. Q: Are bulletproof plates heavy and uncomfortable to wear?

A: While some bulletproof plates can be heavy, advancements in material technology have led to lighter and more comfortable options.

3. Q: Can civilians purchase bulletproof plates?

A: Yes, civilians can purchase bulletproof plates in many regions, but the laws and regulations surrounding their purchase may vary.

4. Q: Do bulletproof plates require regular maintenance?

A: Yes, regular maintenance and inspection are crucial to ensure the plates remain effective and reliable.

5. Q: Are bulletproof plates legal to use in all situations?

A: The legality of using bulletproof plates depends on the laws and regulations of the specific region or country.